600-680

Max. feeding size (mm)100-600

Capacity (t/h)115.5-164.5

machine power(kw)

Limestone

Basalt

Granite

Cobblestone

Construction

Power plant

Dry mixing

Chemica

Construction

Mining

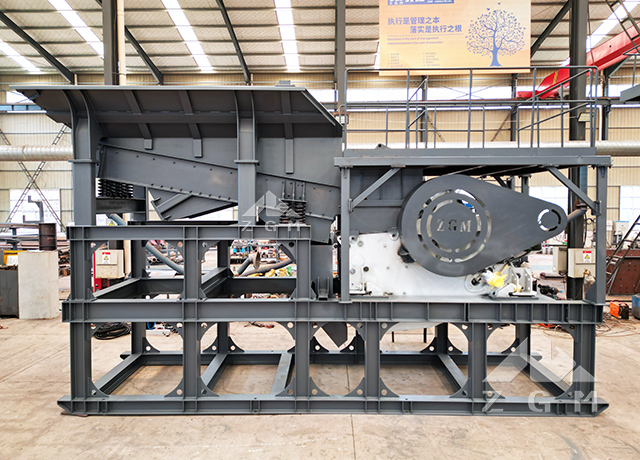

ZK-J series module type jaw crushing mobile station is a framable crushing station mainly launched by China Base Industry according to customers' needs for site, production cycle, operation characteristics, transition and rapid production. This crushing station covers a small space, low investment cost. And it can meet the container, flat truck and other transport modes. The machine realizes the no-foundation installation on the production site, saves the production cost and time of concrete foundation, effectively avoids the repetitive infrastructure investment, and greatly reduces the pre-production cost.

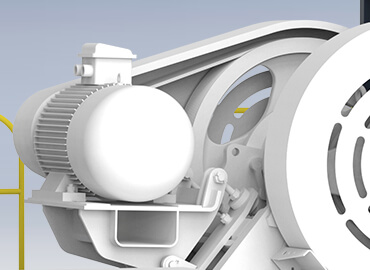

The whole machine has strong integration and special modular design, saving about 80% of organization and installation time, and saving about 60% of installation labor cost.

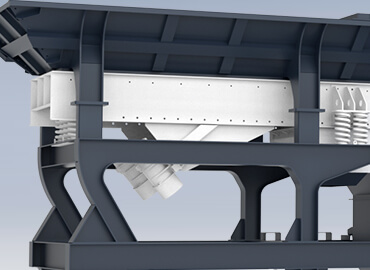

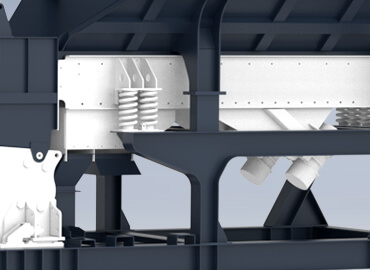

Adopt high quality thickened frame type steel frame structure to protect smooth operation and extend the service life of equipment.

The modular frame crushing station is easy to disassemble and transfer, and can be quickly moved to a new working location by means of transport.

Various process plan configuration, each module part can be applied to a single multi-terminal online application, according to the needs of the formation of different crushing and screening system.

| Model | Main machine model |

Main belt conveyor |

Feeding capacity (t/h) |

Max. feeding size (mm) |

Capacity(t/h) | Adjusting range of discharge opening(mm) |

Main machine power(kw) |

Whole machine power(kw) |

Transportation dimension (L×W×H)(mm) |

| ZK-J96 | J6S96 | B800*9m | 300 | 600 | 100-330 | 70-200 | 90 | 115.5 | 13000*5300*3950 |

| ZK-J106 | J6S106 | B1000*9m | 430 | 650 | 140-420 | 70-200 | 110 | 137.5 | 14000*5300*3950 |

| ZK-J116 | J6S116 | B1200*10m | 600 | 680 | 170-600 | 80-200 | 132 | 164.5 | 15000*6000*4300 |

A professional team deeply understands customer needs and recommends suitable products to customers

After signing the order, provide the demand form to the facilities department and count the categories before leaving the factory

Inventory of required components for equipment, technical protocol comparison inspection, and process testing

Before the delivery of the complete set of equipment, installation, debugging, and self inspection must be completed

Standardize equipment installation, debugging, and maintenance work to ensure personal and equipment safety

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright