60-180

Capacity(t/h)Hydraulic lift

Hydraulic systemRCYD(C)-6.5

Iron Remover

Limestone

Basalt

Granite

Cobblestone

Construction

Power plant

Dry mixing

Chemica

Construction

Mining

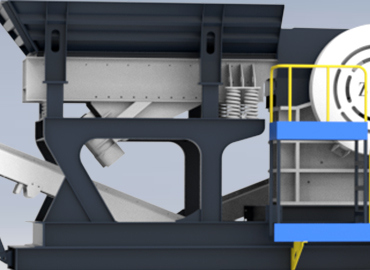

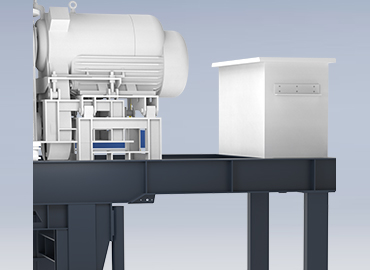

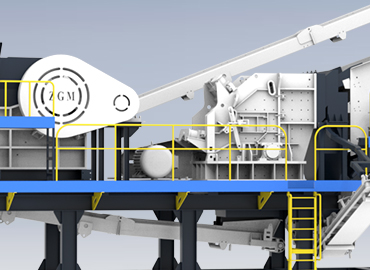

The Modular Integrated Crushing Station is designed to integrate four equipment units, capable of handling 50-200 tons per hour. Featuring a unified modular frame design, the feeding, coarse crushing, and screening modules are interchangeable. Depending on the material type—soft rock or hard rock—either an appropriate impact crusher or cone crusher is employed. Its modular structure eliminates the need for concrete foundations, significantly saving costs and setup time. It enables flexible and convenient site transitions, avoiding repeated investments and achieving rapid deployment with minimal or zero civil works.

Suitable for processing 50-200 tons per hour of soft and hard ores or construction waste.

Each unit is equipped with an independent Vehicle electrical control system, ensuring easy operation and rapid commissioning.

High structural strength and strong versatility, allowing quick production by swapping the main unit.

Equipped with advanced high-performance crushing units that are efficient, high-capacity, reliable, and easy to operate and maintain.

| Model | Feeder Model | Primary Crusher | Second Crusher | Sreen Model | Iron Remover | Belt Conveyors | Capacity(t/h) | Hydraulic system |

| ZK-4 E57C75 | GZD3090 | PE500x750 | CS75 | 3YS1548 | RCYD(C)-6.5 | 5 | 60-90 | Hydraulic lift |

| ZK-4 J80DG100 | GZD3896 | J6S80 | DG100 | 3YS1560 | RCYD(C)-6.5 | 5 | 80-120 | Hydraulic lift |

| ZK-4 E90DG100 | GZD3896 | PE600x900 | DG100 | 3YS1560 | RCYD(C)-6.5 | 5 | 100-120 | Hydraulic lift |

| ZK-4 E90DG160 | GZD3896 | PE600x900 | DG160 | 3YS1560 | RCYD(C)-6.5 | 5 | 150-180 | Hydraulic lift |

A professional team deeply understands customer needs and recommends suitable products to customers

After signing the order, provide the demand form to the facilities department and count the categories before leaving the factory

Inventory of required components for equipment, technical protocol comparison inspection, and process testing

Before the delivery of the complete set of equipment, installation, debugging, and self inspection must be completed

Standardize equipment installation, debugging, and maintenance work to ensure personal and equipment safety

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright