≤560mm

feeding size335-1050t/时h

Capacity≤355kw

Power

Limestone

Basalt

Granite

Cobblestone

Construction

Power plant

Dry mixing

Chemica

Construction

Mining

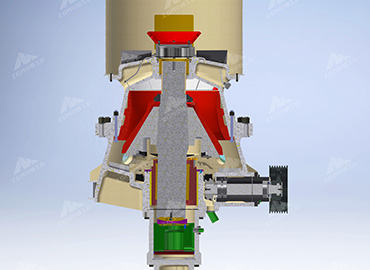

DG series single-cylinder hydraulic cone crusher has a combination of crushing machinery, hydraulic, electrical, automation and intelligent control technology. The machine is the high efficient crusher which is researched and developed independently. widely used in metal and non-metallic minerals, cement, sand, metallurgy and other industries of medium, fine and ultra-fine crushing operations. It has the advantages of high crushing efficiency, low production cost,convenient maintenance and adjustment, excellent grain type of broken products and so on.

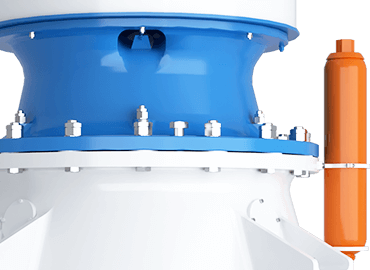

The integrated design of hydraulic pressure station and lubricating station save installation space.

Sliding bearing adopts special oil wedge design, which can avoid direct frictional contact between shaft and bearing.

The machine adopts the principle of laminating crushing, which improves product shape to be cubic.

DG series single cylinder hydraulic cone crusher integrates discharge opening adjustment and overload protection functions as a whole.

| Model | Type of chamber | Max. Feeding size(mm) |

Adjusting range of discharge opening(mm) |

Power(kw) | Capacity (t/h) |

| DG100 | S1 oversize | ≤240 | ≥22 | >≤90 | 85-170 |

| S2 Middle coarse | ≤200 | ≥19 | 70-130 | ||

| H1 fine | ≤135 | ≥10 | 46-130 | ||

| H2 middle fine | ≤65 | ≥8 | 35-80 | ||

| H3 super fine | ≤38 | ≥4 | 27-60 | ||

| DG160 | S1 oversize | ≤360 | ≥25 | ≤160 | 120-345 |

| S2 Middle coarse | ≤300 | ≥22 | 105-305 | ||

| S3 coarse | ≤235 | ≥19 | 90-275 | ||

| H1 fine | ≤185 | ≥13 | 66-210 | ||

| H2 middle fine | ≤90 | ≥10 | 65-165 | ||

| H3 super fine | ≤50 | ≥6 | 48-105 | ||

| DG250 | S1 oversize | ≤450 | ≥35 | ≤250 | 255-605 |

| S2 Middle coarse | ≤400 | ≥29 | 215-515 | ||

| S3 coarse | ≤300 | ≥25 | 190-490 | ||

| H1 fine | ≤215 | ≥16 | 110-395 | ||

| H2 middle fine | ≤110 | ≥13 | 115-340 | ||

| H3 super fine | ≤70 | ≥8 | 90-255 | ||

| DG315 | S1 oversize | ≤560 | ≥41 | ≤315 | 335-1050 |

| S2 Middle coarse | ≤500 | ≥38 | 305-895 | ||

| H1 fine | ≤275 | ≥16 | 170-665 | ||

| H2 middle fine | ≤135 | ≥16 | 190-505 | ||

| H3 super fine | ≤65 | ≥13 | 205-320 | ||

| DG500 | S1 oversize | ≤480 | ≥60 | ≤355 | 500-950 |

| H1 fine | ≤250 | ≥20 | 350-650 | ||

| H2 middle fine | ≤170 | ≥16 | 280-500 | ||

| H3 super fine | ≤100 | ≥12 | 200-450 |

A professional team deeply understands customer needs and recommends suitable products to customers

After signing the order, provide the demand form to the facilities department and count the categories before leaving the factory

Inventory of required components for equipment, technical protocol comparison inspection, and process testing

Before the delivery of the complete set of equipment, installation, debugging, and self inspection must be completed

Standardize equipment installation, debugging, and maintenance work to ensure personal and equipment safety

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright