≤1020mm

Feeding size80~1150t/h

Capacity75-250kw

Power

Limestone

Basalt

Granite

Cobblestone

Construction

Power plant

Dry mixing

Chemica

Construction

Mining

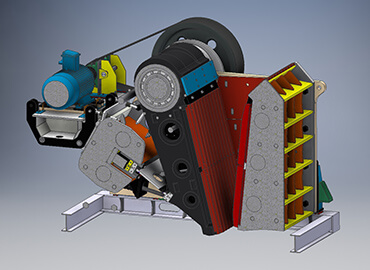

J6S European jaw crusher integrates international advanced crushing technology, processing technology and materials, which is another condensation breakthrough between China and international technology in the field of coarse crushing. Which comprehensive advantages in reliability, stability, output ratio, safety, maintainability will become one of the popular jaw crusher.

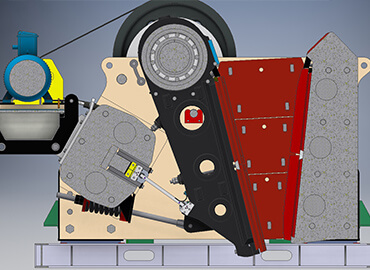

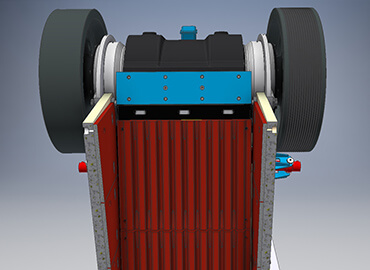

The movable jaw assembly is composed of high-quality steel casting (weld assembly); large flywheel (pulley) adopts in block casting process.

Integral cast steel structure is adopted for bearing seat. The integral bearing seat can't only enhances the radial strength but also reduces cost.

The adoption of tooth-type jaw plate increases the capacity and lengthens the maintenance period of spare parts.

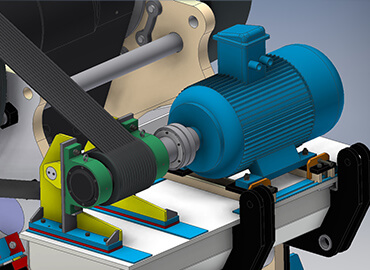

Integrated motor frame, which reduces installation space and length of "V" belt.

| Model | Feeding size(mm) | Max. Input size(mm) | Output size(mm) | Capacity(t/h) | Power(kw)) | Rotate speed(rpm) | Overall Dimension(mm) |

| J6S80 | 520×800 | 420 | 60-150 | 80-290 | 75 | 350 | 2650x1540x1780 |

| J6S100 | 760×1000 | 650 | 70-200 | 140-400 | 110 | 260 | 3670x2420x2490 |

| J6S96 | 580×930 | 480 | 60-175 | 120-325 | 90 | 330 | 2950x2300x1950 |

| J6S106 | 700×1060 | 600 | 70-200 | 140-420 | 110 | 310 | 3230x2440x2590 |

| J6S110 | 850×1100 | 720 | 80-200 | 160-550 | 132 | 230 | 3800x2450x2550 |

| J6S125 | 950×1250 | 800 | 100-250 | 230-760 | 160 | 220 | 4100x2800x3440 |

| J6S130 | 1100×1300 | 950 | 120-260 | 260-780 | 160 | 220 | 4836x2762x3489 |

| J6S145 | 1100×1450 | 920 | 125-275 | 320-950 | 200 | 220 | 4400x3060x3210 |

| J6S160 | 1200×1600 | 1020 | 150-300 | 410-1150 | 250 | 220 | 5700x3650x3550 |

A professional team deeply understands customer needs and recommends suitable products to customers

After signing the order, provide the demand form to the facilities department and count the categories before leaving the factory

Inventory of required components for equipment, technical protocol comparison inspection, and process testing

Before the delivery of the complete set of equipment, installation, debugging, and self inspection must be completed

Standardize equipment installation, debugging, and maintenance work to ensure personal and equipment safety

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright