≤10mm

Selected Granularity100-350t/h

Capacity11-37kw

Power

Limestone

Basalt

Granite

Cobblestone

Construction

Power plant

Dry mixing

Chemica

Construction

Mining

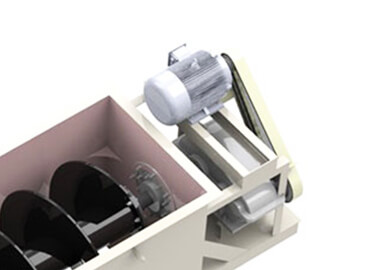

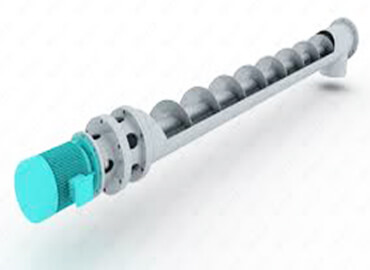

LSX series spiral sand washing machine can clean and separate powder and soil in sand and stone, its novel sealing structure, reliable transmission device, ensure the effect of cleaning and dehydration, and is a kind of high efficiency sand washing equipment used with sand making machine. LSX series spiral sand washing machine has two kinds of single rotation and double rotation. The equipment is characterized by large capacity, small power consumption, high cleanliness, less sand loss during sand washing, and no screen mesh. it is the sand washing industry upgrade ideal choice.

More cleaning effect for washing, compare to wheel sand washer, the materials washing time is longer, and cleaning effect is more better.

Big capacity, the working principle of spiral sand washer isn't collect by wheel bucket, so the handling capacity has been greatly improved.

Higher energy efficiency, reduce the energy loss by wheel bucket, so spiral sand washing machine can make better use of energy.

Reduce the wear of spare parts, spiral sand washer without screen, so without wear of screen mesh, long life for using.

| Model |

Number of Spirals |

Spiral Diameter |

Sink Length |

Selected Granularity |

Processing Capacity |

Spiral Speed |

Motor Power |

Water Consumption |

Weight |

Dimensions |

| LSX-920 | 1 | 920 | 7585 | ≤10 | 100 | 21 | 11 | 10-80 | 6.2 | 8420×2180×3960 |

| 2LSX-920 | 2 | 920 | 7585 | ≤10 | 200 | 21 | 11×2 | 20-160 | 11.5 | 8420×3970×3960 |

| LSX-1120 | 1 | 1120 | 9750 | ≤10 | 175 | 17 | 18.5 | 20-150 | 10.9 | 10770×3950×4860 |

| 2LSX-1120 | 2 | 1120 | 9750 | ≤10 | 350 | 17 | 18.5×2 | 40-300 | 17.8 | 10770×5260×4860 |

A professional team deeply understands customer needs and recommends suitable products to customers

After signing the order, provide the demand form to the facilities department and count the categories before leaving the factory

Inventory of required components for equipment, technical protocol comparison inspection, and process testing

Before the delivery of the complete set of equipment, installation, debugging, and self inspection must be completed

Standardize equipment installation, debugging, and maintenance work to ensure personal and equipment safety

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright