Basalt

Raw material200 t/h

CapacityThree

Finished products

Power

Dry Mix

Chemica

Construction

Mining

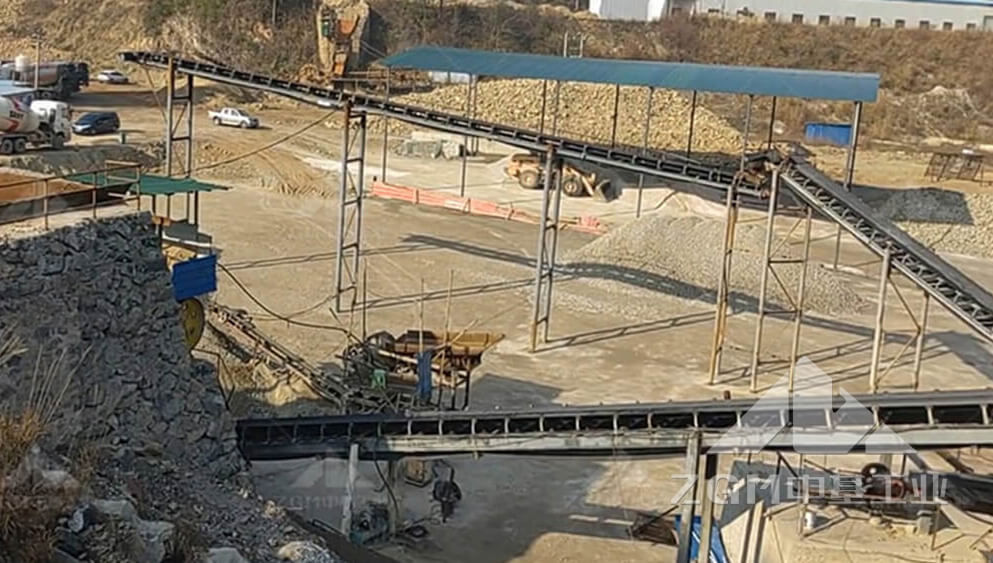

Raw material:basalt

Capacity:200 tons/hour

Finished products:0-5mm,5-16mm,16-35mm

Design: "crushing + shaping" process;

Main equipment: ZSW4211 vibrating feeder +J6S106 jaw crusher +HPS multi-cylinder hydraulic cone crusher +V6S sand making machine +YS2160 vibrating screen

Production status:In the early stage of the project, ZGM Industrial visited customer site to conduct a comprehensive survey, according to the actual environmental characteristics of the customer site, combined with the business philosophy of green production, and optimize the design details of each processing in the project construction planning constantly. In the process of project construction and installation, while ensuring the construction progress, on-site installation guidance, training on the daily for maintenance, precautions of the machine , to ensure the continuous and stable operation of the equipment. Finally, after installation and construction, this production line has been fully completed and put into use as scheduled.

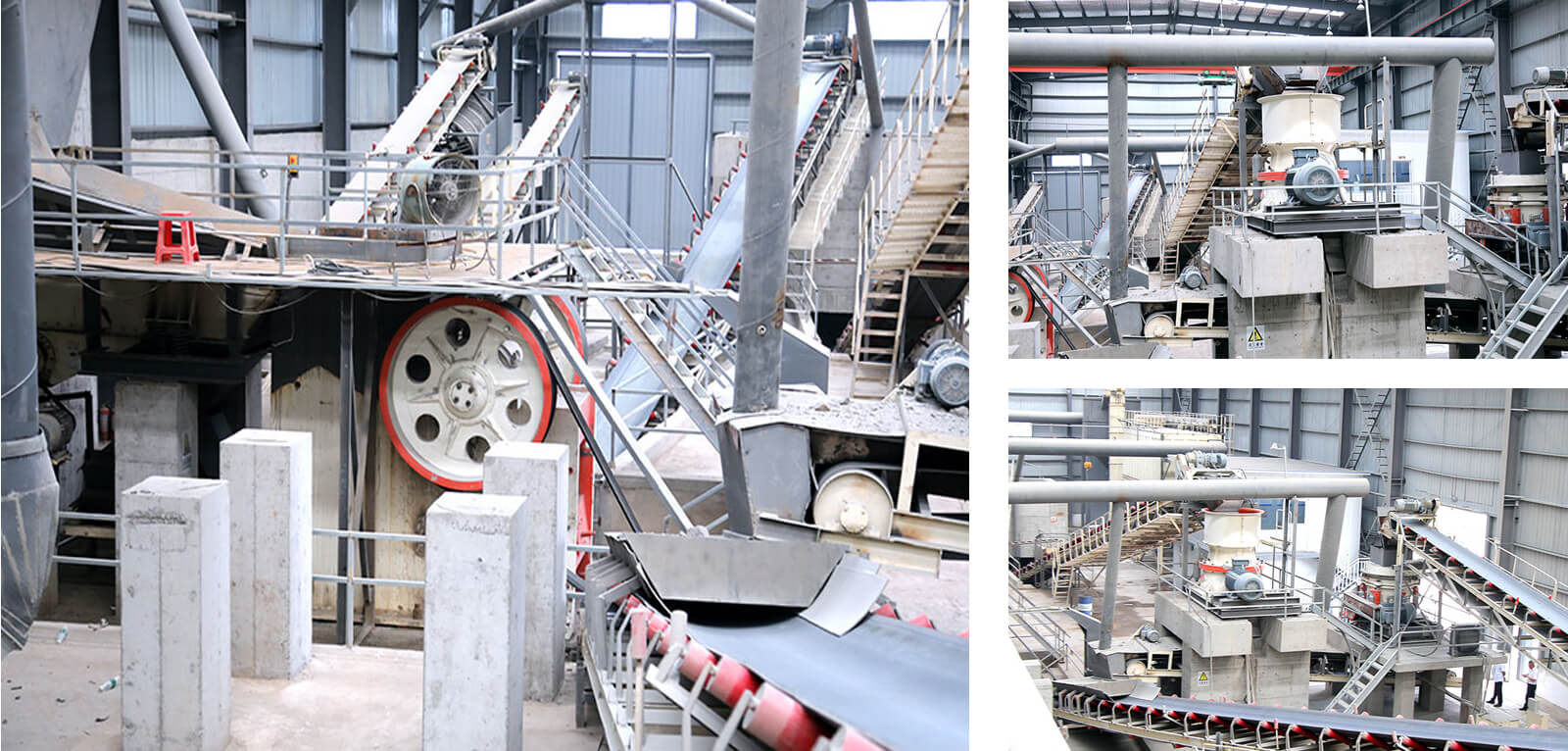

This production line adopts high energy efficiency main crushers, combining multi-stage crushing and sand making process, and the final product grain shape is full and round, fully meeting the use of high-quality aggregate needs. The materials are transported to the European strength jaw crusher for primary crushing through the vibration feeder, and the materials that meet the requirements of the secondary crushing are transported to the HPS multi-cylinder hydraulic cone crusher for secondary crushing. The materials after secondary crushing are separated by the vibrating screen, some semi-finished products are directly entered into the sand making machine for shaping, and the products that meet the requirements enter the finished product area. Those who do not meet the standard should return to the crushing and sand making process again, and finally form three specifications of sand and aggregate with particle size of 0-5mm, 5-16mm, and 16-35mm.

The use of non-oil seal leak-proof structure design, multi-pipe thin oil lubrication, to achieve simultaneous lubrication of upper and lower bearings, significantly improve the service life of bearings.

Discharge port adjustment device is safe and fast. The hydraulic wedge type discharge port adjusting device is used to adjust the size of the discharge port conveniently and improve the maintenance automation. The system is convenient to operate and shorten the downtime when the equipment stops with load due to power supply interruption.

Based on the structure of eccentric sleeve rotating main shaft, the bearing capacity of the equipment is enhanced, and better installed power can be matched with lower noise.

By optimizing the cavity shape and using the principle of laminating crushing to break the material, the laminating crushing efficiency is improved and the wear of wearing parts is further reduced.

ZGM Industry provides you with a complete set of mining equipment and services. If you are interested in our company and products, you are welcome to visit the factory area. We will arrange on-site visits for you to experience the quality of the discharge materials intuitively!

Consult

Service hotline

Address

WEST 100M, THE INTERSECTION BETWEEN QIYUAN RD AND YUXI RD, XINGYANG, ZHENGZHOU, HENAN

©2023 Henan ZGM Industrial Technology Co.,Ltd Copyright